Connectors Lüdecke

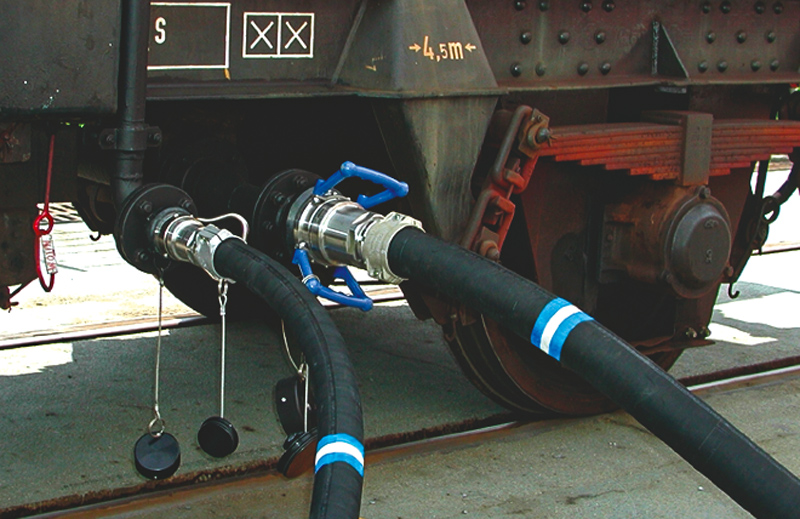

The most widely used and known are couplings from the German manufacturer Lüdecke. Brass couplings are used for air and water, stainless for aggressive media and specific conditions. Pneumatic couplings quickly and safely connect your tools and equipment. GEKA bayonet couplings for water for "profi" and "hobby" use. Tempering quick couplings are used in plastics production, where they are used to connect injection molds. Plug-in quick-release couplings in combination with Lock-On Plus hoses guarantee easy and firm connection without the need for additional buckles.