Gearboxes

Gearboxes connect together the Linear Unit, Drive Set and Motor and ensure users can achieve the correct ratio of input speed, torque and precise carriage positioning for any application. item Gearboxes also help make optimum use of the installation space available. Motors can be fitted in line with the Drive Set or offset at a 90° angle from it.

To ensure reliability and a long service life, item uses only high-quality planetary gearboxes that distribute forces to the gears with low backlash. They are also compact, very quiet and have a maintenance-free design.

The compact, maintenance-free planetary gearboxes are each available in three fixed gear ratios – 1:3, 1:5 and 1:7.

The Gearboxes run quietly and have a long service life. They are maintenance free and do not require additional lubrication. The compact Gearboxes is suitable for very high input speeds up to 18,000 RPM.

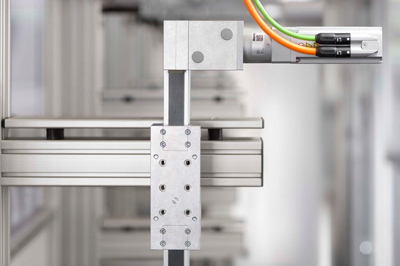

Gearboxes AP (AxialPlanetengetriebe) connect a Motor with a Drive Set along a shared axis.

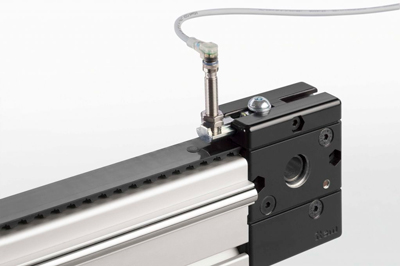

Bewel Gearboxes WP (WinklPlanetengetriebe) connect a Motor with a Drive Set at a 90° angle.