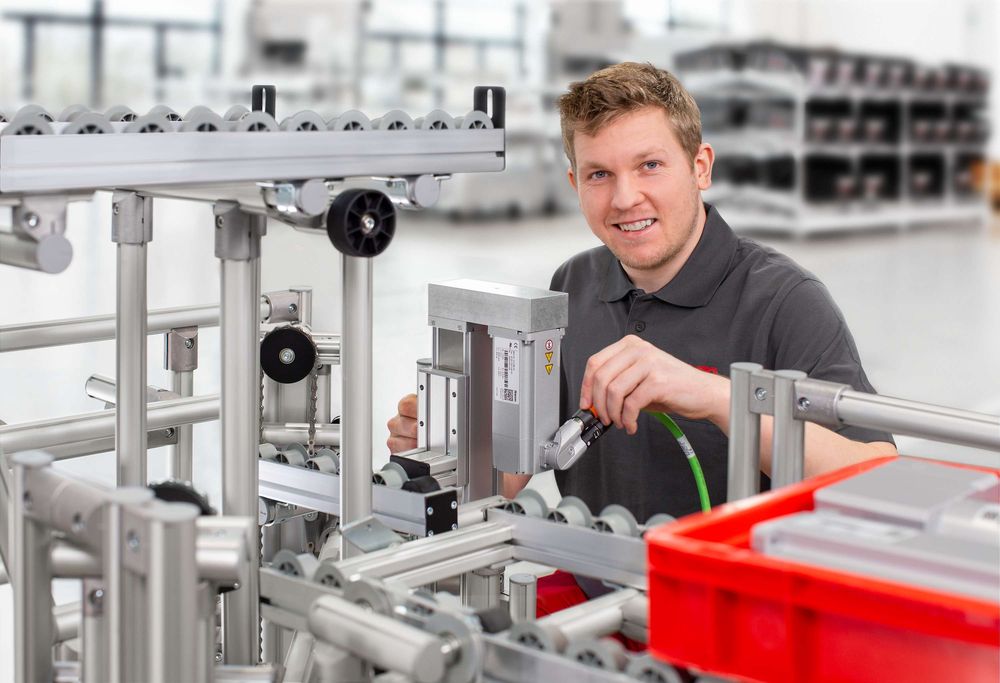

Wide range of accessories for conveyors

A large selection of optional accessories allows us to design the conveyor exactly according to your needs.

Standard mechanical accessories

- various types of underlying sheets under the process belt

- belt and chain guidance without or with integrated sidewall

- additional side guides adjustable both horizontally and vertically

- various types of base structures

Standard electrical accessories

- motor connection via frequency converter

- motor connection via motor starter

- STOP button for each operator workstation

- sensor for product registration on a conveyor in the end or in any working position

- various drive positions relative to the conveyor

Process, Modular and Plate Bands

- wide selection of materials with different mechanical and chemical resistance

- wide choice of transport layer design

- wide selection of belts