Advantages

- high load capacity

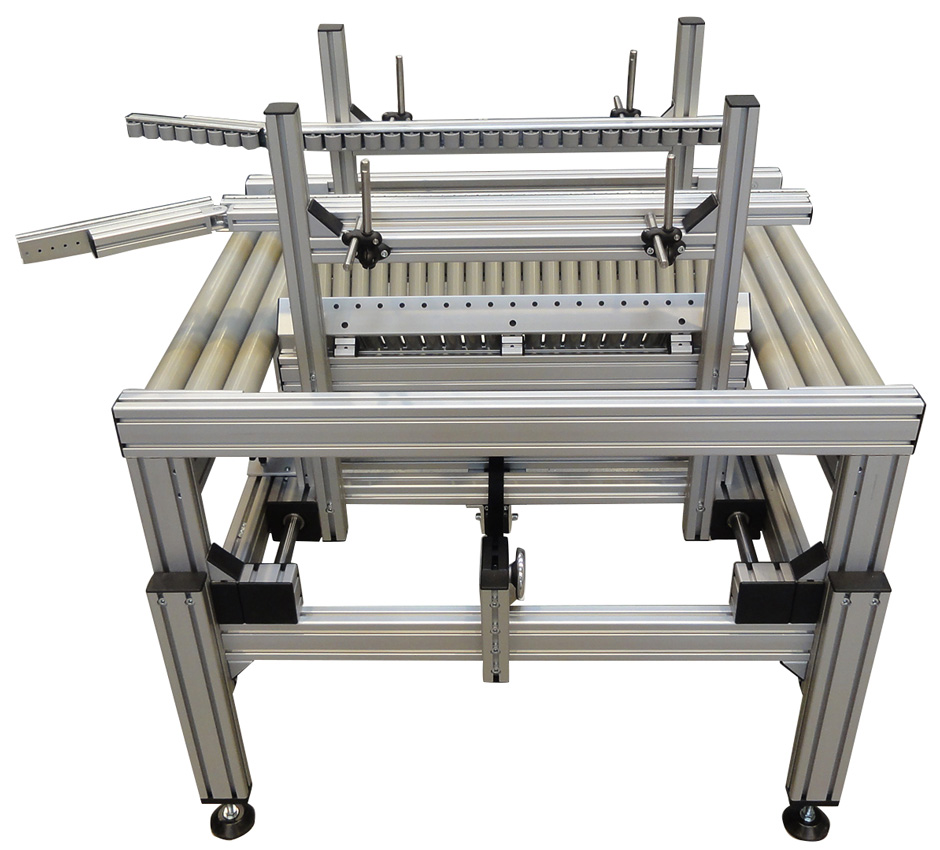

- robust design

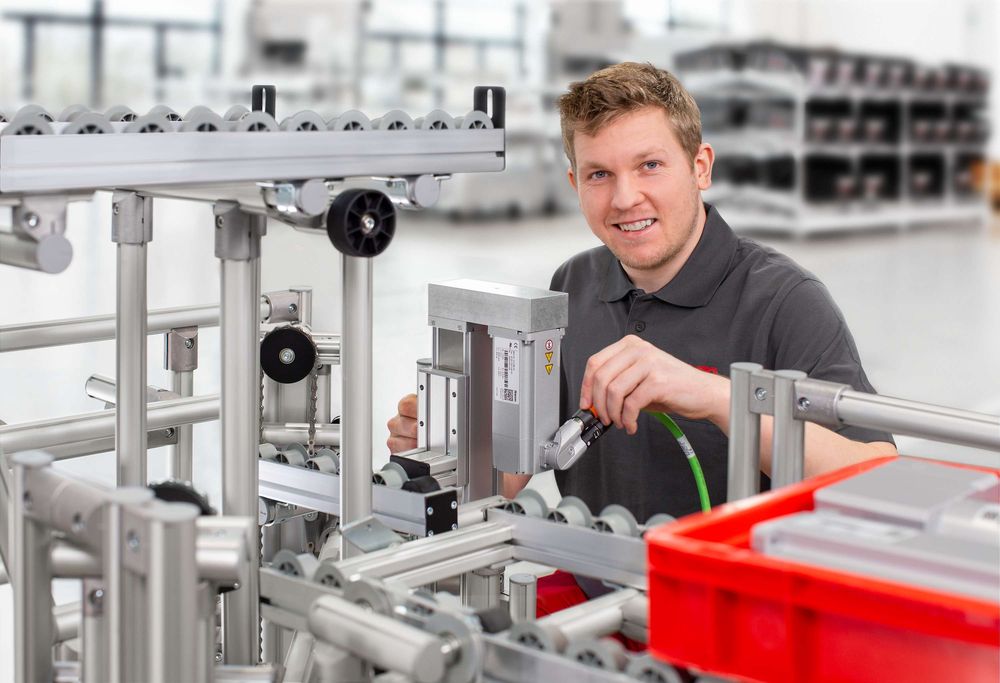

- conveyors are manufactured according to customer requirements, ie. "made-to-measure"

- possibility to perform special technological and manufacturing operations directly on the conveyor (eg. blowing, degreasing, draining the oil into the tub under the conveyor, etc.)

- conveyor skeleton made of item modular system profiles with the possibility of easily connecting other profiles or complementary technologies, possibility to modify the conveyor in the future