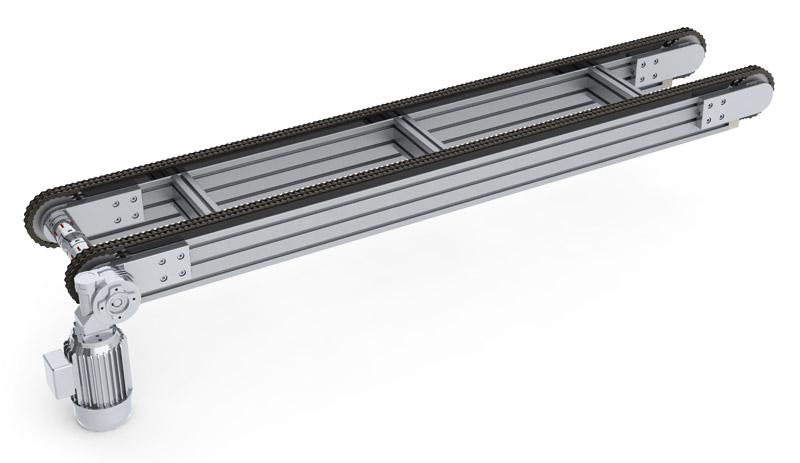

Chain conveyor 40CD MS

| Standard parameters | |

| Conveyor Total Length | 500 – 6 000 mm |

| Frame Width | 200 – 1 000 mm |

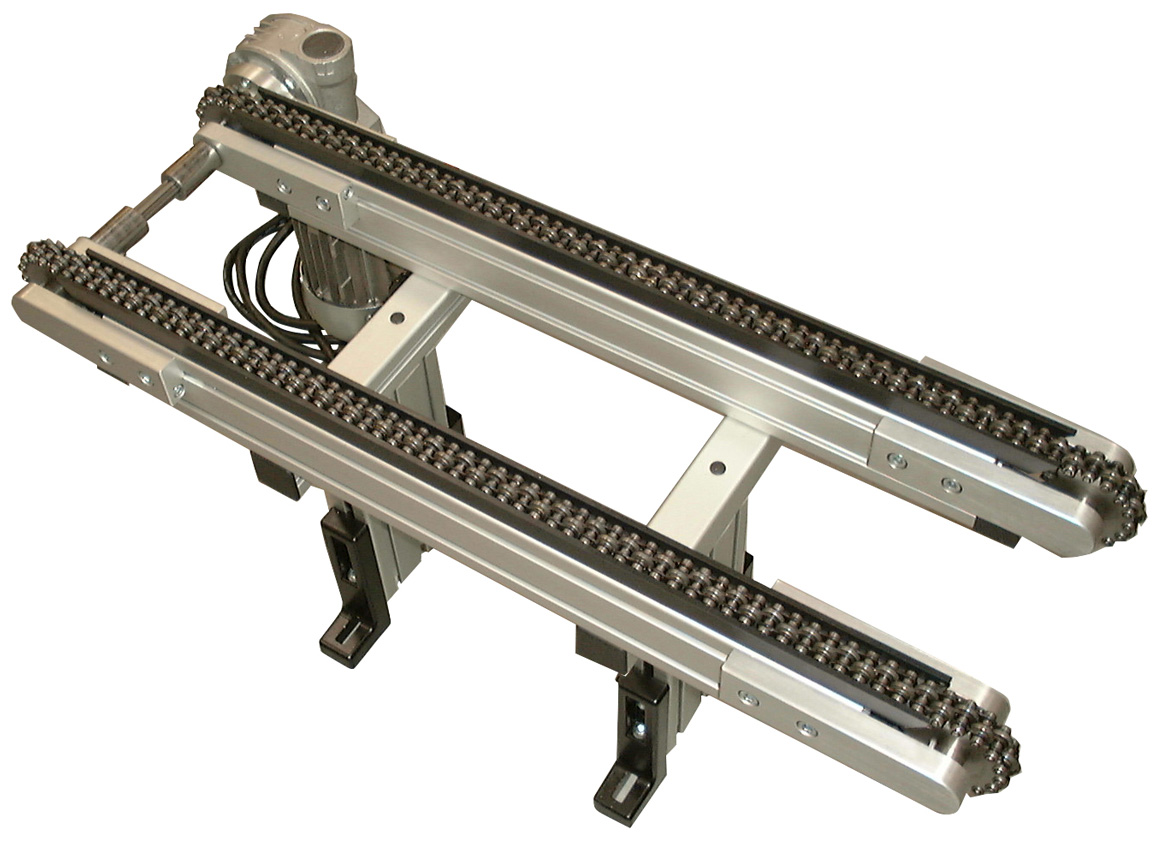

| Conveyor Load | 15 kg/m - plastic rollers, 20 kg/m - steel rollers |

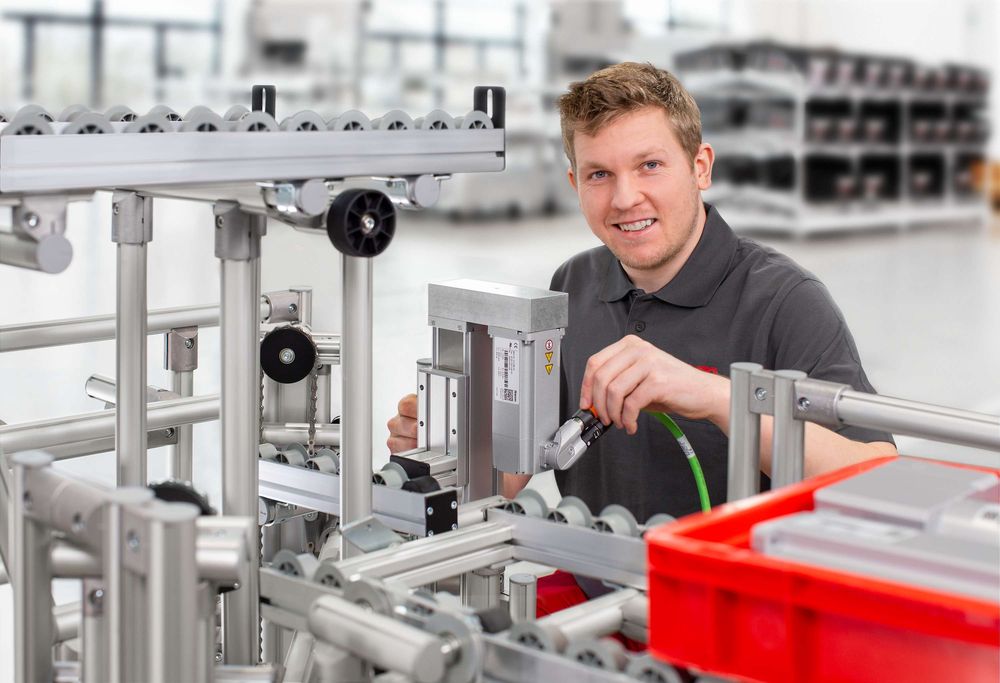

| Drive | 3 x 400 V (1 x 230 V) |

| Belt Speed * | 4 – 43 m/min |

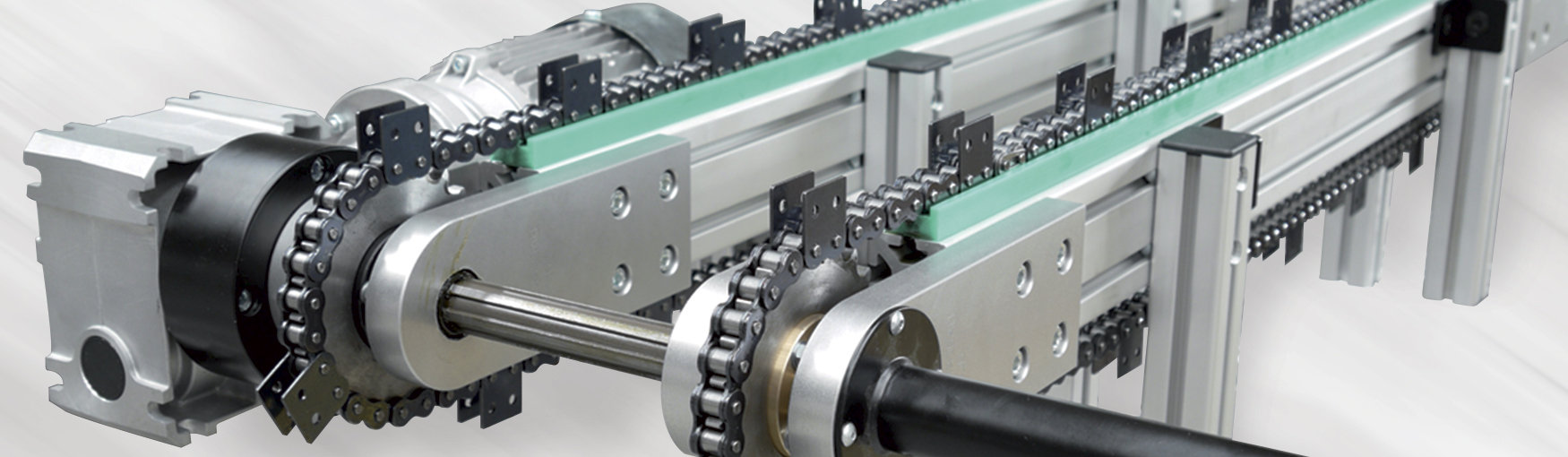

| Chain | Accumulation Chain with Plastic or Steel Rollers |

| Ambient Temperature | 10 – 60 °C |

| Pitch Diameter of Sprockets | 65,1 mm |

| * Possibility of Speed Regulation by Frequency Converter in the Range from 40 to 150% (Nominal Speed =100%). The above figures are standard. Other values on request. |

|

![]() Demand form

Demand form